Laser die cutting

General information

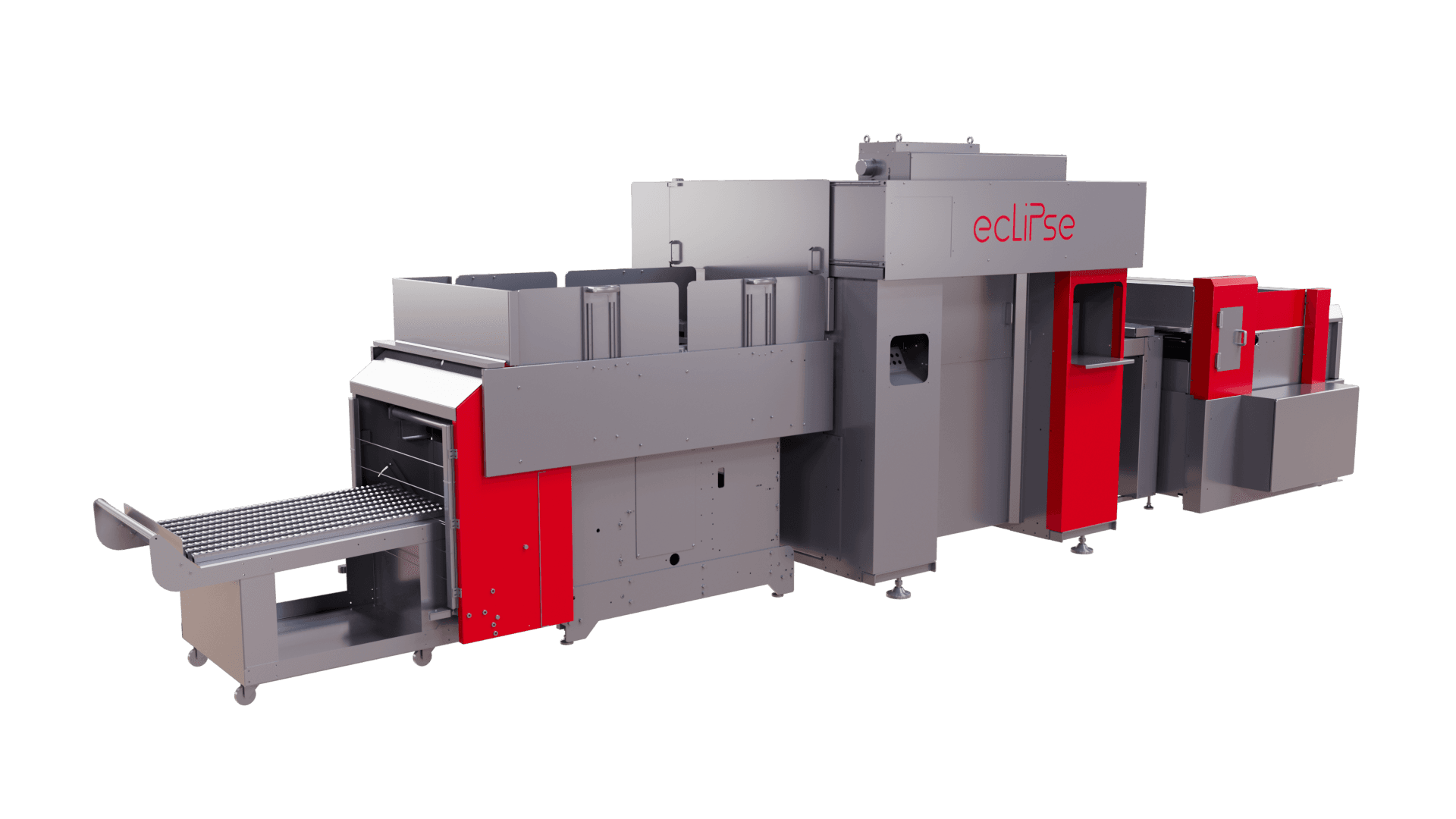

Creasing and cutting in one powerful, automated solution.

The Eclipse laser die-cutting system combines automatic creasing and precision laser cutting in one modular, high-performance machine – available in B3, B2 and B1 formats.

At the heart of the machine is a pallet feeder with barcode recognition, which initiates a seamless, non-stop programming sequence for all subsequent operations. The soft-wash system efficiently removes any smoke residue from the laser process, ensuring clean, professional sheets.

Optional modules enable stripping and blanking, while multiple outputs allow you to deliver either the full sheet or neatly stacked final jobs.

SEVEN REASONS TO CHOOSE ECLIPSE:

1. Automated die-cutting workflow

No interruptions between jobs – Eclipse delivers dynamic, fluid and flexible production.

2. Cost-efficiency for all run sizes

Streamlines processes and reduces costs, making even single-sheet or short runs profitable.

3. Unmatched graphic freedom

Produce high-quality, creative products using a wide range of materials and thicknesses.

4. Order flexibility

Easily manage diverse client requests with speed and accuracy.

5. End-to-end versatility

From sample prototyping to large production runs – all on the same machine.

6. Simple, low-cost operation

Minimises tooling and setup requirements. The intuitive system can be run by designers or typesetters, even remotely.

7. Scalable configurations

Choose from four standard models or request custom configurations to suit your workflow.

Machines

All configurations of the Eclipse

Eclipse B1

Handles B1 sheets with full automation, advanced stacking, and up to 4 creasing cameras. Ideal for high-volume, high-complexity production with large sheets and demanding jobs.

Eclipse B2

A solid balance of speed and capability for B2 format jobs. Features 2 creasing cameras, barcode automation, and reliable performance at 1,500 sheets/hour.

Eclipse B2 Plus

Processes up to 3,000 sheets/hour with ultra-fast changeovers, 4 creasing cameras, and smart automation. A premium choice for large-volume workflows needing speed and precision.

Eclipse B3

B3 handles B3 formats with ease. Includes barcode automation and all core functions, perfect for short runs and prototyping.